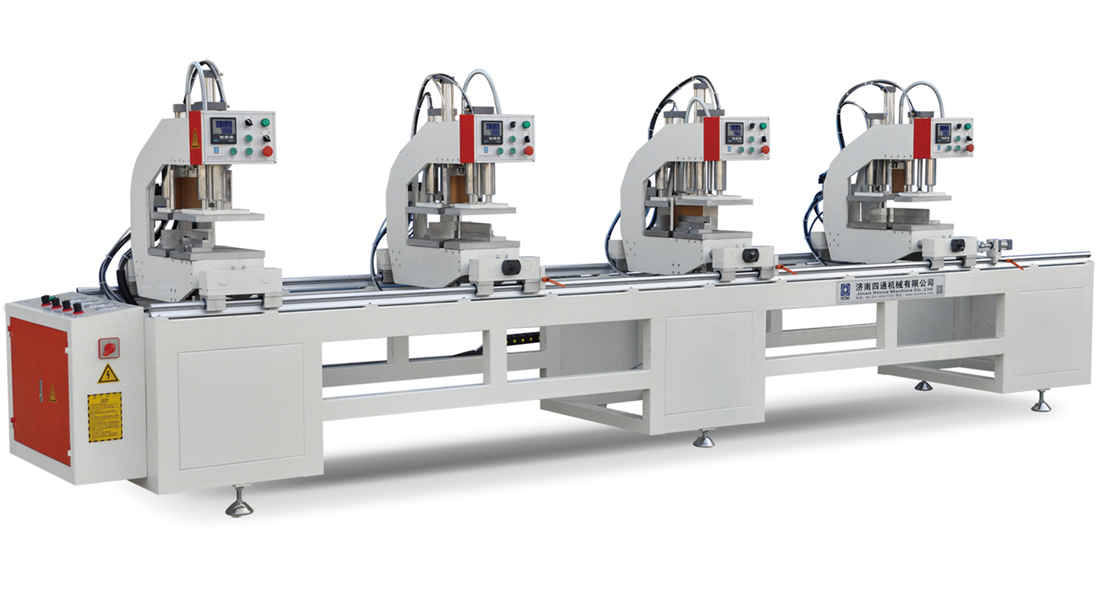

Four-head Welding Machine is a special machine for processing uPVC doors and windows. The machine guarantees the welding strength, welding accuracy and durability of uPVC windows and doors through PLC programmer control, pneumatic driving system, and high-accuracy liner bearing motional pairs. The movements of profile clamping, profile melting, and frame fabricating are controlled by a PLC, and all the movements are finished one by one automatically, easy to operate. Additionally, good-performance and long-life pneumatic components, industrial PLC in control system, and high-strength machine construction, guarantee the service life of the uPVC window welding machine. The machine is one of essential uPVC window manufacturing machines.

Features

Can weld the shape of ┏, ┏┓, ┏┳┓, ┳┳┳┳, ╋╋╋╋.

All welding heads can work independently and simultaneously.

Support arms for each welding head.

Can weld any angle from 30°-180°with special locating plate.

Pressure, temperature and welding time can be adjusted manually according to different uPVC profiles and external environmental condition.

Welding movements are controlled by PLC, with high stability.

Main Parameter of Four Head Welding Machine.

Technical Parameter

Working Air Pressure: 0.4-0.6MPa

Air Consumption: 200L/min

Power Supply: 380V/220V 50Hz

Input Power: 4.5KW

Welding Profile Height: 20-100mm

Welding Profile Width Max: 200mm

Welding Dimension Range: 400-4300mm

Outside Dimension: 5300*1000*1700mm

The uPVC window welding machine is major and essential equipment for manufacturing uPVC windows and doors. The machine heats the end of uPVC profiles into molten state through heating plates, and then fabricates the uPVC profiles into a window frame unit or window sash unit by pressing. The movements of profile clamping, profile melting, and frame fabricating are controlled by a PLC, and all the movements are finished step by step automatically. Welding is the most important step for making uPVC windows and doors, and the welding quality (such as welding strength, welding-angle accuracy, window size accuracy) will affect the finished window quality directly. STONE Window Machinery guarantees the welding quality of the uPVC window welding machine through use of high-quality heating plates and temperature controllers, high accuracy liner bearing motional pairs and other high quality machine components, and through our strict quality control system.

中文

中文 English

English Deutsch

Deutsch Español

Español العربية

العربية Français

Français Português

Português Русский

Русский Italia

Italia 日本語

日本語  한국어

한국어