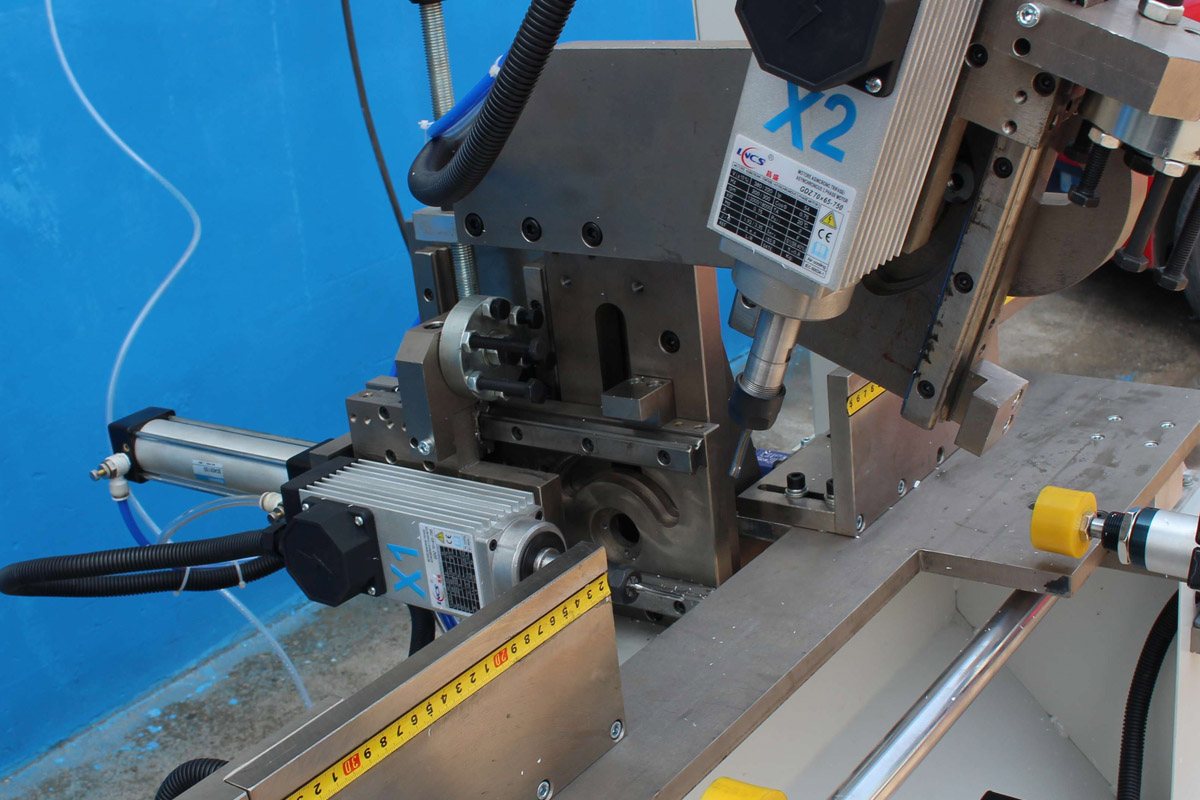

This machine is a specialized processing equipment for plastic door and window profile drainage grooves and air pressure balance grooves. The equipment has two independently working milling machine heads, with the lower machine head capable of converting two positions horizontally through a driving cylinder. The two machine heads can operate independently or linkage, and can be freely selected according to work needs. The processing of the drainage groove and pressure balance groove can be completed with one clamping of the profile.

Technical Parameter

Power supply: 220V 50Hz (optional)

Input power: 0.8Kw*2

Air pressure: 0.5-0.8Mpa

Air consumption: 95L/min

Number of milling heads: 2

Milling cutter diameter: 5mm

Motor rotational speed: 18000r/min

Depth of slots: Max. 30mm

Length of slots: Max. 60mm

Outside dimension: 1060*1150*1650mm

uPVC window milling machines are used to process hardware installation holes and slots, water slots, air-pressure balance grooves and other holes or slots in uPVC windows and doors, and it is an important component part of uPVC window production line. Milling hardware holes or slots and water-slots of windows is an important step in window-door manufacturing procedure. The quality of these holes or slots will have a direct influence on the quality of windows and doors. Qualified hardware holes and slots not only improve the visual sense of beauty of uPVC windows and doors, but guarantee the fastness and durability of hardware which increases the safety factor of windows and doors. uPVC window milling machines include water slot milling machine, lock hole & slot milling machine, copy routing machine, and so on.

中文

中文 English

English Deutsch

Deutsch Español

Español العربية

العربية Français

Français Português

Português Русский

Русский Italia

Italia 日本語

日本語  한국어

한국어