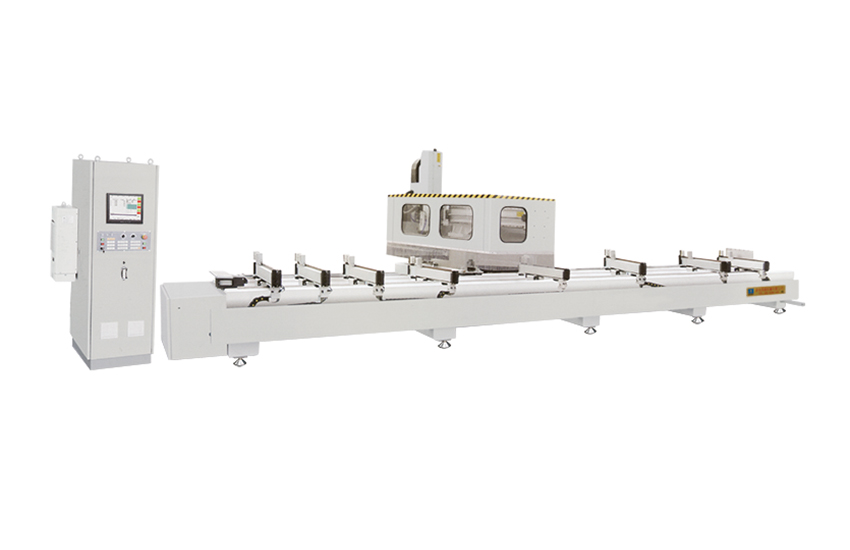

The CNC Double Worktable 3-axis Processing Center is designed for processing water slots, mounting holes, lock holes in curtain wall aluminum profiles, industry aluminum profiles, nonferrous metal and light section steel structure materials. This aluminum processing center can design and process special shaped grooves and holes through the graphics software carried in the machine, or though importing graphics data made by other graphics software (such as CAD).

Features

Complete servo control system and imported spindle motor guarantee the quality.

Drilling, milling and tapping can be finished in one loading and clamping.

High quality steel tube is adopted in the machine frame after hot processing which is better stabilization and rigidity.

Double locating device makes the machine working continuously with profile input alternately.

Sensors for machine head and operating persons make sure the safety of worker.

Technical Parameter

Power supply: 380V 50Hz (optional)

Input power: 10Kw

X-axes range: 7000mm

X-axes speed: 0~50m/min

Y-axes travel: 400mm

Y-axes speed: 0~30m/min

Z-axes travel: 300mm

Z-axes speed: 0~20m/min

Outside dimension: 11300×2350×2550mm

Weight (about): 4500Kg

Aluminum curtain wall machine is a mechanical equipment used for manufacturing and installing aluminum alloy curtain walls. It includes the main processes in the curtain wall production process, such as profile cutting, corner code production, curtain wall assembly, curtain wall installation, etc. The use of aluminum curtain wall equipment can help achieve engineering and automated production of curtain walls, improve construction efficiency and quality.

中文

中文 English

English Deutsch

Deutsch Español

Español العربية

العربية Français

Français Português

Português Русский

Русский Italia

Italia 日本語

日本語  한국어

한국어